Products >> Hollow Fiber UF Membrane Module >> PVDF UF Membrane Module

MAX 80 Analog

- Product No.:TFMAX105AG

Analog: Hydranautics HYDRAcap MAX 80

General Information

Hydranautics HYDRAcap MAX 80 analog ultrafiltration (UF) membrane module TFMAX105AG is a pressurized module, which is designed and manufactured for the filtration of surface water, potable water, seawater and industrial wastewater. These UF modules are made of new generation PVDF hollow fiber membrane with high fouling resistance and hydrophilicity.

Features

- Outside-to-inside flow direction

- New generation PVDF hollow fiber

- Uniform pore size of 0.08 μm

- Typical filtrate turbidity ≤ 0.1 NTU

- Bacteria removal ≥ 4 log

Advantages

- High tolerance for feed water

- High-quality filtrate

- Less energy needed for high flux

- Longer service life by high fouling resistance and mechanical strength

- Economical analog module for direct replacement of Hydranautics HYDRAcap MAX 80

Applications

- Surface water

- Potable water

- Beverage clarification

- Industrial wastewater

- Reclaimed water reuse

- Pre-treatment of seawater desalination

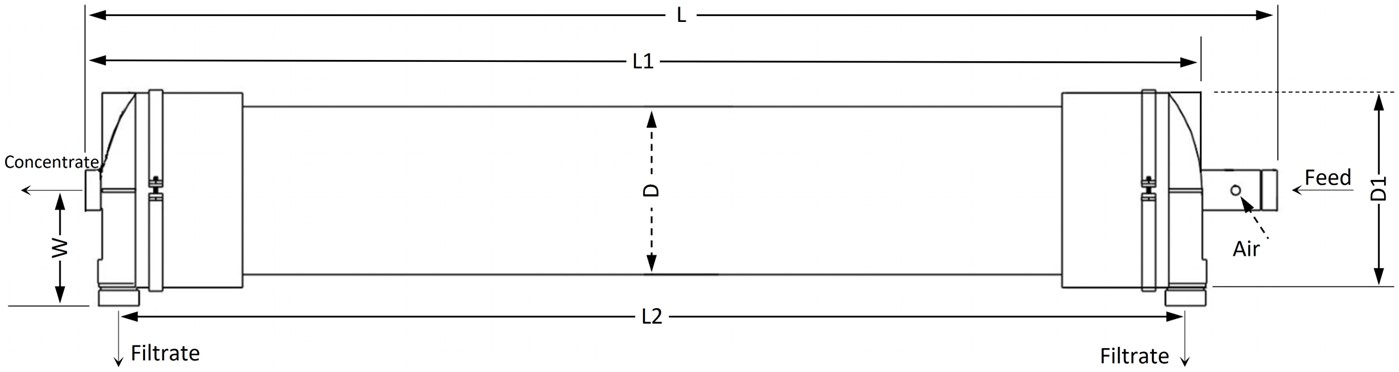

Module Dimensions

|

Model |

L (mm/in) |

L1 (mm/in) |

L2 (mm/in) |

D (mm/in) |

D1 (mm/in) |

W (mm/in) |

Connection port |

Air inlet |

|

TFMAX105AG |

2340.6/92.15 |

2232.7/87.9 |

2110.9/83.11 |

250/9.84 |

290/11.42 |

172/6.8 |

DN50 (2” Victaulic) |

3/8” FNPT |

Specifications

|

Specifications |

Parameters |

|

Model |

TFMAX105AG |

|

Effective membrane area (m²/ft²) |

105/1130 |

|

Filtrate flow rate m3/h (gpm) |

3.6 - 12.6 (15.7 - 55.5) |

|

Dry weight (KG/lbs) |

62/135 |

|

Wet weight filled with water (KG/lbs) |

118/260 |

|

Membrane material |

PVDF (Polyvinylidene Fluoride) |

|

Fiber ID/OD |

0.6/1.2 mm (0.024/0.047 inch) |

|

Flow direction |

Outside-in |

|

Pore size |

0.08 μm |

|

Housing material |

UPVC |

|

Potting material |

Epoxy resin |

Operating and Cleaning Limits

|

Type of operation |

Dead-end flow or cross flow |

|

Typical flux (25°C) |

34 - 120 L/m2·h (20 - 71 gfd) |

|

Temperature |

1 - 40°C (34 - 104°F) |

|

Maximum feed pressure (20°C) |

5 bar (73 psi) |

|

Maximum feed pressure (40°C) |

3 bar (44 psi) |

|

Maximum trans-membrane pressure |

2 bar (30 psi) |

|

Backwash flux (25°C) |

75 - 120 L/m2·h (48 - 71 gfd) |

|

Maximum backwash pressure |

2.5 bar (36 psi) |

|

Maximum air scour feed pressure |

2.5 bar (36 psi) |

|

Air scour flow |

12.3 - 15.4 Nm3/h (7.3 - 9.1 acfm) |

|

Air scour duration |

2 - 4 minutes |

|

Air scour frequency |

Once every 20 - 60 minutes |

|

pH-Continuous operation @25°C |

2 - 11 |

|

pH-Cleaning @25°C |

1 - 13 |

|

Maintenance cleaning frequency |

1 - 3 times per day |

|

Maintenance clean duration |

20 - 30 minutes |

|

Disinfection chemicals |

NaOCl, ClO2 or NH2Cl |

|

Cleaning chemicals |

NaOH, HCl, H2SO4 or citric acid |

|

Instantaneous chlorine tolerance |

5,000 ppm |

|

Maximum chlorine exposure |

750,000 ppm-hrs |

|

Maximum feed TSS |

100 ppm |

|

Maximum feed turbidity |

300 NTU |

|

Maximum feed particle size |

300 µm |

|

Filtrate SDI15 |

≤ 2.5 |

|

Filtrate turbidity |

≤ 0.1 NTU |

We offer various UF membrane module analogs. If you and your customer accept Hydranautics HYDRAcap MAX80 analog ultrafiltration membrane, please send us an inquiry now.

Products Category

Contact Us

Name: International Sales Dept.

Tel: +86-27-8673 0002

Fax: +86-27-8732 0476

E-mail: [email protected]

Add: 4th Floor, Baofeng Ages, 1045 Jiefang Blvd, Qiaokou District, Wuhan, Hubei Province, 430030, China

Mail inquiry

Mail inquiry